About Solar Panels

Current electricity demand in the US is mostly met by consuming fossil fuels like oil and gas, but we are nearing the brink of exhausting these nonrenewable resources as our planet’s population continues to rise. Luckily, renewable resources like solar energy are steadily becoming a larger part of our country's energy profile, and since solar energy comes from the sun, it represents a limitless source of power. In just one hour, the amount of solar power delivered by the sun is more than the entire world uses in a year!

To harness the sunlight and generate power for your home or business, a solar photovoltaic (PV) system is required. These are also known as solar panel systems, solar energy systems, and solar power systems, and all of them start with the most recognizable part of the PV system: solar modules (known more commonly as solar panels).

More About Solar Modules

Solar modules/panels are made up of an assembly of connected solar cells, and these are the blue or black “squares” seen on modules/panels. Solar cells are typically made of silicon, an element with conductive properties that generates an electrical current when exposed to sunlight, also known as the photovoltaic effect. An array is created when solar modules/panels are grouped together in a series or in parallel on a roof or ground mount.

Number Of Cells

Most solar modules/panels in the residential and commercial markets are made up of 60 or 72 solar (photovoltaic) cells, although there are certainly other grid sizes available. Choosing the right type and number of solar panels depends mainly on the energy requirement (how much power is needed), available space for the solar module/panel array, and budget constraints.

Types of Solar Cells

The most common types of solar modules/panels are monocrystalline, polycrystalline and thin-film, and their differences start during the creation process.

Monocrystalline silicon is created by slowly extracting a monocrystalline silicon ingot out of melted silicon. This cylinder of high-purity silicon is then sliced into thin wafers for use as solar cells.

Polycrystalline silicon is created through a simpler process. Instead of using the slow and more expensive process of creating a single ingot, molten silicon is poured into a square mold and cooled before being sliced into thin wafers that are perfect squares.

Thin-film panels are made by depositing one or more thin layers of photovoltaic material on a substrate, and these materials are usually silicon, cadmium telluride (CdTe), copper indium gallium selenide (CIGS), or organic photovoltaic cells (OPC).

Here is a quick comparison of the three based on the following criteria:

- Apperance

Monocrystalline cells have a dark uniform colour that typically show up as black, but polycrystalline cells have visible differences in color shades due to the varied crystal structure, and they typically show up as blue. Monocrystalline and polycrystalline cells are rigid and as a result, the panels do not bend.

Thin-film cells are diffused onto a substrate with very thin layers, and the panels will look almost solid in color with very narrow lines. These lines are formed by the chemical etching process that produce each cell, and the completed panel is fairly flexible.

- Cost

Monocrystalline solar cells cost more than polycrystalline solar cells of the same size. Thin-film solar cells are cheaper than both monocrystalline or polycrystalline.

- Efficiency

Due to being made from one large crystal as opposed to many small ones, monocrystalline cells have a higher efficiency (typically 15% to 20%) than polycrystalline cells (typically 13% to 16%). In addition to better overall efficiency, monocrystalline panels tend to perform better than polycrystalline panels in high ambient temperatures. Thin-film cells are the least efficient (typically 7% to 9%) in terms of power production.

- Size

Since monocrystalline cells are more efficient than polycrystalline cells, the size of a monocrystalline solar module/panel is less than a polycrystalline module/panel of the same wattage. In other words,if you are limited on space and want to generate the most power possible, monocrystalline modules/panels are the way to go. Thin-film modules/panels require the most space to produce the same results as either a monocrystalline or polycrystalline module/panel.

- Longevity

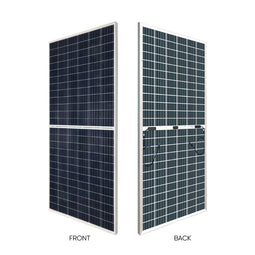

Bifacial

Bifacial Mono Crystalline

Mono Crystalline Poly Crystalline

Poly Crystalline Thin Film

Thin Film Foldable Solar Panel

Foldable Solar Panel Residential On Grid

Residential On Grid Commercial On Grid

Commercial On Grid Solar Storage / Hybrid Inverter

Solar Storage / Hybrid Inverter Solar Battery Inverter

Solar Battery Inverter RV Off Grid Solar Inverter

RV Off Grid Solar Inverter Lithium ion Batteries

Lithium ion Batteries AGM Batteries

AGM Batteries Lead Acid Batteries

Lead Acid Batteries Lithium Batteries

Lithium Batteries Lead Carbon Batteries

Lead Carbon Batteries Deep Cycle Flooded Battery

Deep Cycle Flooded Battery Solar Workstation

Solar Workstation Solar Security Camera

Solar Security Camera Solar Freezer

Solar Freezer Battery Charger

Battery Charger Meters

Meters Distribution Panel

Distribution Panel Battery

Battery Invertor Charger

Invertor Charger Breaker Panel

Breaker Panel